Why the Steel We Use Matters: 1011 vs 1010 in Lavatory Hangers

The Bottom Line

Small material decisions make a big difference.

At MaterialsNest our lavatory hangers from Steel 1010, we ensure:

Superior strength

Better dimensional stability

Long-lasting reliability

It’s one more reason our products stand out—and why professionals trust them for dependable installations.

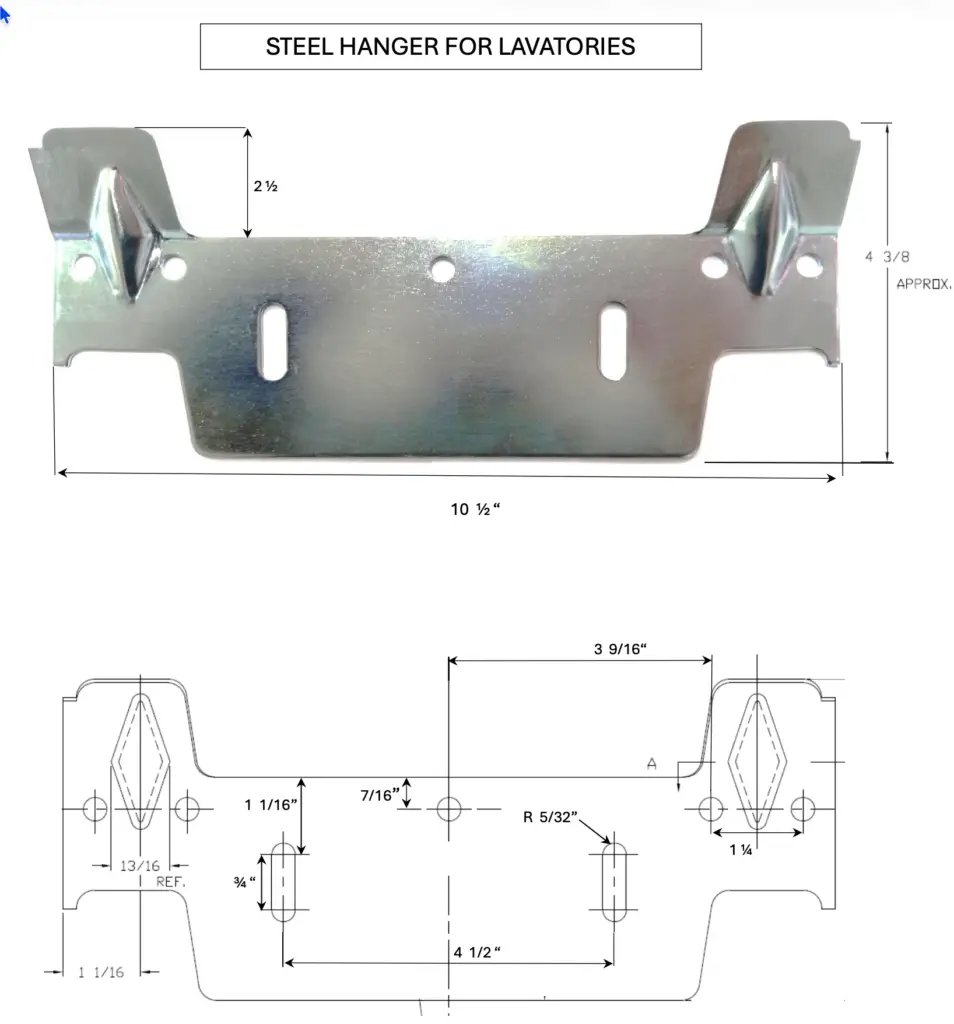

Steel 1010 Lavatory Hangers: The Industry-Standard Choice for Reliable Plumbing Support

When it comes to plumbing hardware and installation components, material selection is not optional—it is critical. For lavatory hangers, even small variations in steel composition can affect load performance, dimensional stability, and long-term reliability.

That is why MaterialsNest distributes lavatory hangers manufactured from Steel 1010, the preferred low-carbon steel used across the plumbing, construction, and fixture-manufacturing industries.

Below, we explain why Steel 1010 is the right material, how it compares to similar grades, and why professionals rely on it for dependable installations.

Understanding Low-Carbon Steel in Plumbing Hardware

Steel 1010 and Steel 1011 are both classified as low-carbon steels, commonly used in:

Plumbing support hardware

Metal stamping and forming

Construction fasteners and brackets

OEM and industrial fabrication

Carbon Content Comparison

Steel 1010: ~0.08% – 0.13% carbon

Steel 1011: ~0.10% – 0.14% carbon

While the difference appears minor, the plumbing industry overwhelmingly specifies Steel 1010 for lavatory hangers and similar support components because it delivers the ideal balance of strength, formability, and compliance with industry standards.

Why Steel 1010 Is the Correct Material for Lavatory Hangers

Lavatory hangers are structural components. Their job is to support weight, maintain alignment, and perform consistently over time—often in commercial and residential environments where failure is not acceptable.

1. Proven Load Performance for Plumbing Fixtures

Steel 1010 provides stable, predictable tensile strength that meets the load requirements of:

Wall-mounted sinks

Commercial lavatories

Residential plumbing fixtures

Its mechanical properties ensure:

Reliable weight support

Minimal risk of cracking or brittle failure

Safe performance under static loads

This is why plumbing contractors and inspectors expect Steel 1010.

2. Superior Formability and Shape Control

Steel 1010 is widely used because it is:

Highly ductile

Easy to bend, stamp, and form

Resistant to cracking during manufacturing

This results in:

Accurate hanger geometry

Consistent dimensions

Easier installation with proper alignment

For plumbers and installers, that means cleaner installs and fewer adjustments on site.

3. Excellent Weldability and Manufacturing Consistency

Steel 1010 is known for its exceptional weldability, making it ideal for mass-produced plumbing hardware.

Benefits include:

Strong, reliable weld joints

Repeatable production quality

Tight tolerances across large production runs

This consistency is essential for manufacturers, distributors, and wholesalers supplying standardized plumbing components.

4. Long-Term Durability in Real-World Installations

Plumbing hardware is expected to last for years—often decades.

Steel 1010 offers:

Good fatigue resistance

Stable performance under continuous load

Reliable behavior in typical indoor plumbing environments

This translates into:

Fewer callbacks for contractors

Lower replacement rates

Greater confidence for builders and facility managers

Why MaterialsNest Uses Steel 1010 — Not Alternatives

Some materials may offer slightly higher strength on paper, but they are not what the plumbing industry specifies or requires.

At MaterialsNest, we distribute lavatory hangers made from Steel 1010 because it is:

✔ The industry-accepted material

✔ Easy to install and weld

✔ Reliable under real installation conditions

✔ Compatible with plumbing codes and common practices

We focus on what works in the field, not over-engineering or cutting corners.

Who Uses Steel 1010 Lavatory Hangers?

Our Steel 1010 lavatory hangers are trusted by:

Plumbing contractors

Commercial builders

Residential developers

OEM plumbing manufacturers

Industrial and construction supply distributors

Maintenance and facilities teams

These professionals choose Steel 1010 because it meets specifications, performs consistently, and installs efficiently.

The Bottom Line

Material choice matters—especially in plumbing support hardware.

By distributing Steel 1010 lavatory hangers, MaterialsNest delivers:

Industry-standard compliance

Reliable load performance

Excellent formability and weldability

Long-term durability professionals can trust

That’s why Steel 1010 remains the correct material for lavatory hangers—and why MaterialsNest is a dependable source for plumbing and industrial metal components.