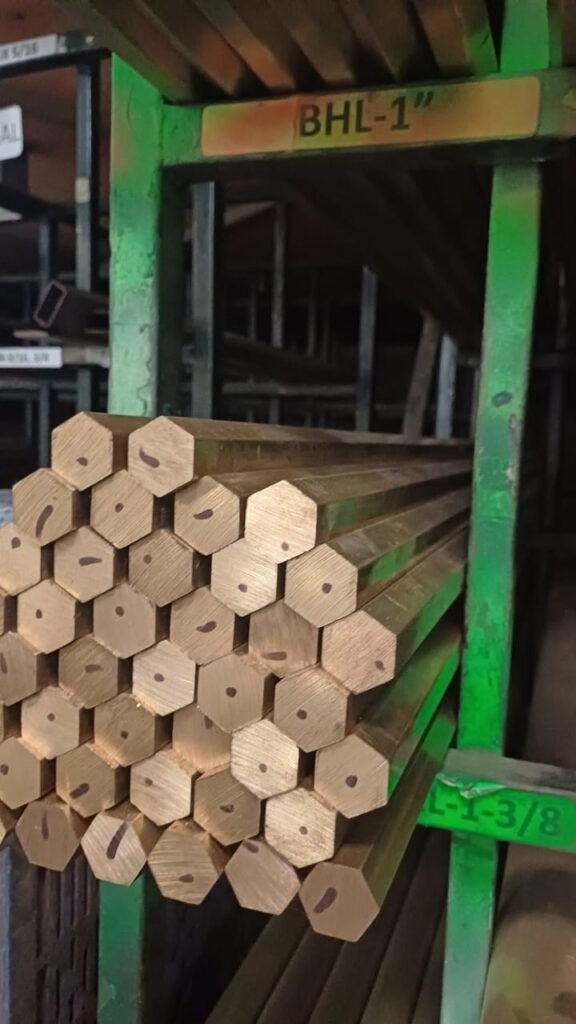

In machining and fabrication, material waste directly impacts cost, efficiency, and lead times. One of the simplest ways to reduce waste—often overlooked—is choosing the right standard bar length. This is why 12 ft brass bars are widely preferred across CNC machining, plumbing, and industrial manufacturing operations.

Standard Length = Better Yield

Most machining shops design cut plans around standard stock sizes. A 12 ft brass bar allows:

Optimized cut nesting

Fewer offcuts and scrap pieces

Consistent part lengths across production runs

Compared to random or shorter lengths, 12 ft stock provides maximum usable material per bar, especially for high-volume machining.

Fewer Splices, Cleaner Machining

Longer brass bars reduce the need for:

Multiple setups

Material splicing

Additional fixturing

This results in cleaner machining operations, improved dimensional consistency, and lower labor time per part—critical for CNC and automatic lathe environments.

Reduced Handling and Inventory Waste

Using a consistent 12 ft length simplifies:

Warehouse storage

Inventory forecasting

Purchasing cycles

Instead of managing mixed or custom lengths, buyers can standardize on 12 ft brass round, hex, and square bars, reducing leftover stock that often becomes unusable.

Ideal for Machining-Grade Brass Alloys

Machining-friendly alloys such as 360 brass perform best when supplied in straight, uniform bars. The 12 ft length:

Minimizes bowing and distortion

Improves chip control

Supports high-speed cutting with less vibration

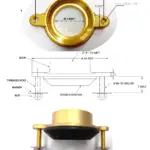

This makes 12 ft brass bars a preferred choice for producing fittings, precision components, spuds, and threaded parts.

Supporting Downstream Components

Standard bar lengths also improve efficiency when machining complementary components such as brass spuds and when pairing with steel hangers in plumbing and mechanical assemblies. Consistency at the raw-material level translates into smoother downstream fabrication and installation.

Why Buy 12 ft Brass Bars from MaterialsNest

MaterialsNest supplies high-quality brass round, hex, and square bars in standard 12 ft lengths, designed specifically for industrial and machining applications. Our products are:

Sourced for consistency and machinability

Offered in commonly used diameters

Suitable for CNC, plumbing, and general manufacturing

By choosing MaterialsNest, buyers gain access to reliable brass stock that helps reduce waste, improve yield, and control production costs—without compromising material quality.

Final Thought

Material waste isn’t always caused by poor machining—it often starts with the wrong stock choice. 12 ft brass bars remain an industry standard because they deliver better yield, cleaner cuts, and more predictable results. For manufacturers focused on efficiency, they’re not just convenient—they’re essential.